-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How to Specify

- How to Install

- How to Maintain

- Projects

- Contact

Introducing New Growth ™ Feature Timbers, and a bold new look too.

Timber Weatherboards Versus Fibre Cement Weatherboards

Fibre cement products are often touted as “more durable” alternatives to natural timber.

The truth is, that in New Zealand timber cladding has been used for over 100 years, and many well maintained houses in New Zealand feature natural timber weatherboards well over 50 years old.

Warranties published by manufacturers of both fibre cement and pine weatherboard indicate they have comparable warranties of around 25 years.

Some large corporate manufacturers of fibre cement weatherboards and cladding systems use their superior marketing budgets to push through the concept that fibre cement based products are somehow superior and more durable than painted natural timber products.

However most New Zealand based timber weatherboard manufacturers are able to provide a 15 year warranty on paint finish – similar to that offered by the leading fibre cement manufacturers.

One of the major drawbacks of fibre cement weatherboard is the finish quality. Unlike natural timber that can be machined to a perfect finish, fibre cement weatherboards typically exhibit a less than smooth finish. The slightly uneven surface of fibre cement cladding catches the light, effectively cheapening a paint finish façade.

Builders are required to use heavier tools and dust extraction on site, which sometimes leads to higher installation costs.

Where fibre cement board products have traditionally held an advantage is in stability. Normal primed pine timber weatherboards are not suitable to be painted with darker colours – the extra heat causes the paint system to fail, the boards to move and resin to “bleed” from the timber itself.

Abodo have provided a natural timber solution – Vulcan Primed Cladding is thermally modified for stability and durability, meaning it can be coated with dark colours.

One advantage fibre cement products continue to hold is fire retardancy as they are generally non combustible. Watch this space though, Abodo is working on a fire retardant natural cladding solution for the future.

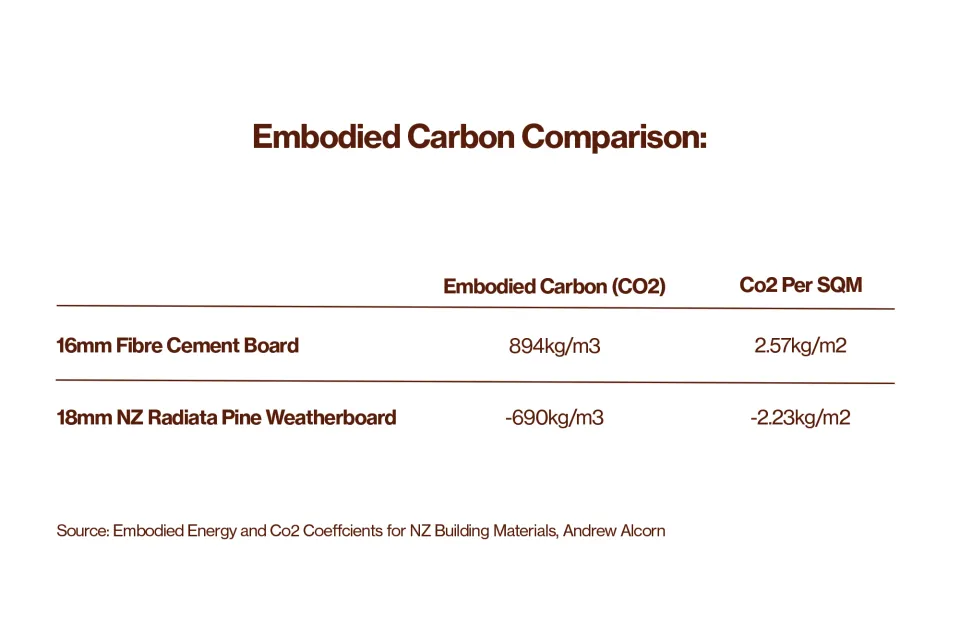

In a climate conscious era, the embodied carbon emitted, or stored in building materials is becoming important. Wood products store carbon, where more intensive products like fibre cement emit carbon - to reduce our carbon emissions we should choose biogenic materials, like sustainably grown timber.

A quick summary of the pros and cons of timber weatherboards versus fibre cement board weatherboards:

Timber Weatherboards

Pros:

- Premium finish

- Light weight

- Acceptable durability

- Low carbon footprint

Cons:

- Cannot be coated with dark colours (unless Abodo’s Vulcan Primed (paint finish) or Ebony and Nero Protector Oil finishes are used)

- Non fire retardant

Fibre Cement Weatherboards

Pros:

- Can be coated with darker colours

- Fire retardant

- Acceptable durability

Cons:

- Not a perfectly smooth finish

- Higher carbon footprint than New Zealand Pine

- Heavier weight

- Silica dust is a serious health and safety concern