-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How to Specify

- How to Install

- How to Maintain

- Projects

- Contact

Vulcan’s Unique Vertical Grain

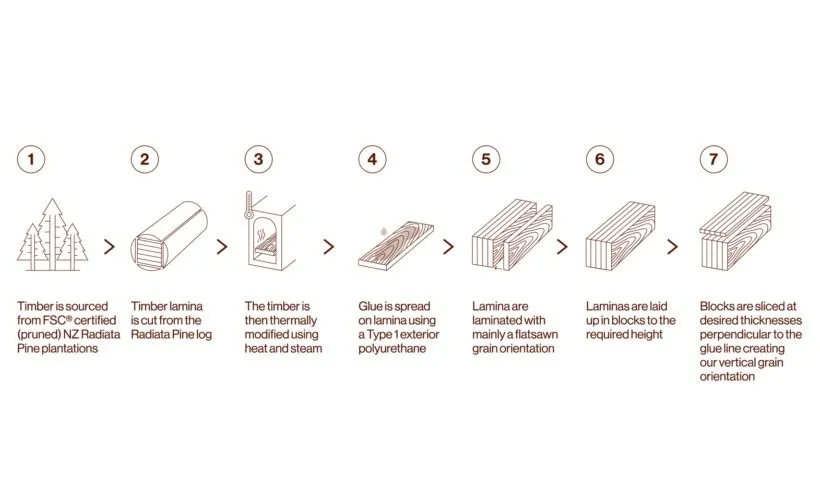

Abodo uses a patented process to carefully craft Vulcan timber’s unique vertical grain orientation.

Vulcan’s unique design is informed by nature for lasting beauty. Abodo uses a patented process to further the longevity and resilience of its Vulcan products through lamination and vertical grain orientation.

This deep dive into the process is broken down into three key parts:

- Understanding the nature of trees

- How Vulcan’s vertical grain works in service

- Our patented solution extends the life of Vulcan timber

1. Understanding the nature of trees

The process starts with knowledge that as trees grow, they experience wind resistance perpendicular to the grain running up the tree.

This means a vertical grain cut of timber from the log will have more strength and stability in service.

We take flatsawn clear grade cuts of timber and further engineer them to add even more strength and stability to Vulcan timber.

2. How Vulcan’s vertical grain works in service

Once exposed to weather, a board will move and cup along the curve of the grain, in a curve similar to a rainbow.

Additionally, surface cracking will occur perpendicular to the grain, causing moisture to penetrate the wood along the grain’s curve.

This can be clearly seen here in these two contrasting timber boards - which are made from typical CCA H3.2 treated pine.

The upper, flatsawn board has experienced deep cracking and cupping through exposure to the outdoors, while the lower, vertical grain cut timber has just minimal surface cracking despite being exposed to the same conditions over the same time period.

3. Our patented solution extends the life of Vulcan timber

Boards cut from New Zealand FSC® certified Radiata Pine logs are thermally modified to improve the performance characteristics including durability and stability.

Following that, to further enhance the strength and longevity of our Vulcan products, we use a patented face-laminating method that joins mainly flatsawn grain timber lengthways into blocks.

For this lamination step we use a low VOC (Volatile Organic Compounds), Type 1 exterior polyurethane adhesive.

Next, Abodo Vulcan boards are cut to the required thickness from the laminated blocks. These cuts are made perpendicular to the glue line to create a board with predominantly vertical grain orientation.

In addition to increased stability and improved weathering characteristics, this allows for a range of possible timber dimensions and a wide variety of practical uses, freeing up architects and designers to create unique forms.

Boosted by our thermal modification process, this patented unique vertical grain orientation means Abodo Vulcan remains exceptionally strong and true through many years of exposure to all weathers and climates.